Do you want to replace your footwear every few months? Do you want to invest in a pair of boots that are not only durable but also comfortable? If yes, you must have heard of HAIX – the brand winning hearts worldwide with its top-notch boots and shoes. From military personnel to firefighters, law enforcement officers to outdoor enthusiasts – everyone loves HAIX! But have you ever wondered where are HAIX boots made and what makes them stand out? In this exciting blog post, we will take you on a journey through the HAIX production process. We’ll start at the company’s headquarters in Germany and travel worldwide to visit their factories in Europe and the USA. So, please sit back, relax, and let’s dive into the world of HAIX boots!

Table of Contents

ToggleThe History of HAIX Boots

HAIX is a German footwear brand specializing in creating functional and protective boots for various sectors, including the military, law enforcement, firefighting, forestry, emergency medical services, and outdoor recreation. The company was established in 1948 by Xaver Haimerl, a master shoemaker who started his business in a small workshop in Mainburg, Bavaria. Initially, he produced shoes for farmers and local workers. Eventually, he expanded his range to include boots for firefighters and soldiers.

In the 1990s, HAIX transformed under the leadership of Xaver’s son, Ewald Haimerl. To improve the performance and comfort of HAIX boots, he introduced new technologies and innovations, such as Gore-Tex membranes, composite toe caps, and arch support systems. He also invested in modern machinery and facilities and expanded HAIX’s production capacity and global market. Today, HAIX is one of the world’s leading footwear brands, with over 1,300 employees and an annual turnover of more than 150 million euros. Millions of customers wear HAIX boots in over 90 countries. Their quality and safety standards have earned them numerous awards and certifications.

HAIX Headquarters: Where are HAIX Boots Made?

The story of HAIX started in 1948 when Xaver Haimerl, a master shoemaker, founded a small workshop in Mainburg, Germany. He began by making shoes for farmers and locals, using traditional methods and materials. Over the years, his son Ewald Haimerl joined the business and expanded it to produce boots for firefighters and soldiers. In 1992, Ewald’s son, Xaver, took over the company and renamed it HAIX, combining his first name and surname. He also introduced new technologies and innovations, such as Gore-Tex membranes, Sun Reflect systems, and Climate systems, to make the boots more comfortable and functional. Today, HAIX remains a family-owned business, with Xaver Haimerl as the CEO and his wife, Daniela Haimerl, as the CFO. The Mainburg headquarters is where the design, development, and quality control of HAIX boots take place. It is also home to the HAIX Academy, a training center for employees and customers.

The Production Process of HAIX Boots

The production process of HAIX boots is one of the main reasons why they are so popular and trusted. It combines traditional craftsmanship with state-of-the-art technology. HAIX boots are manufactured in two locations: Mainburg, Germany, and Mala Subotica, Croatia. Both factories follow the same high standards and strict quality control measures, using the same materials and components.

HAIX boots are made from carefully selected leather, which is sourced from European tanneries that comply with environmental and social regulations. The leather is then treated in-house, using natural and synthetic agents, to ensure its durability, water-resistance, and breathability. The leather is then cut, stitched, and assembled with other elements such as linings, membranes, insoles, toe caps, and soles, using advanced machines and skilled workers.

The production process of HAIX boots can be divided into several stages, each involving different techniques and tools. Here is a brief overview of each stage:

HAIX Headquarters:

This is where the design, development, and management of HAIX boots take place. The HAIX headquarters in Mainburg houses the offices, the research and development center, the testing laboratory, and the warehouse. Here, the HAIX team creates new models and prototypes, tests them for functionality and quality, and coordinates the production and distribution of HAIX boots worldwide.

Handmade Meets High-Tech:

This is where the leather processing and cutting take place. The leather is inspected, sorted, conditioned, and then cut into precise shapes and sizes using automated machines or manual tools. The cut pieces are then marked and prepared for the next stage.

Leather Processing:

This is where the leather stitching and assembly take place. The leather pieces are sewn together, using industrial sewing machines or hand-sewing techniques, to form the upper part of the boot. The upper is then attached to the lining and the membrane, which provide insulation, waterproofing, and breathability. The upper is also reinforced with additional elements, such as toe caps, heel counters, and ankle protectors, to enhance the stability and safety of the boot.

Lining and Membrane:

This is where the lining and the membrane are integrated into the boot. The lining is a soft and smooth material that covers the inside of the boot, providing comfort and cushioning for the foot. The membrane is a thin and porous layer that is sandwiched between the lining and the leather, preventing water from entering the boot while allowing moisture and vapor to escape. HAIX boots use Gore-Tex membranes, which are the most advanced and reliable membranes in the market, offering superior performance and durability.

Manufacturing:

This is where the sole and the insole are attached to the boot. The sole is the bottom part of the boot, which provides traction, shock absorption, and resistance to abrasion, heat, and chemicals. The insole is the removable layer that lies on top of the sole, providing support and cushioning for the foot. HAIX boots use different types of soles and insoles, depending on the intended use and the specific requirements of the boot. The sole and the insole are bonded to the upper using a special adhesive or a direct injection method, creating a strong and seamless connection.

Quality Control:

This is where the final inspection and testing of the boot take place. The boot is checked for any defects or flaws, such as loose threads, uneven stitching, or faulty components. They are also subjected to various tests, such as water-tightness, pressure, and temperature, to ensure their functionality and quality. The boot is then cleaned, polished, and packed, ready to be shipped to the customers.

Centrifuge Testing:

This is a special test that HAIX boots undergo to verify their water-tightness and durability. The boot is filled with water and then spun at a high speed in a centrifuge machine, creating a strong centrifugal force. The boot is then inspected for any leaks or damages which indicate a failure of the boot. HAIX boots are expected to pass this test as proof of their excellence and reliability.

Social Audit:

This is a process that HAIX boots undergo to ensure their compliance with ethical and social standards. The HAIX factories in Germany and Croatia are regularly audited by independent and certified organizations, such as the Business Social Compliance Initiative (BSCI) and the Leather Working Group (LWG), which evaluate the working conditions, the environmental impact, and the social responsibility of the production sites. HAIX boots are certified by these organizations as a sign of their commitment to sustainability and fair trade.

The Features and Benefits of HAIX Boots

Protection:

Comfort:

Durability:

Best of HAIX Boots: Top Picks

HAIX Scout 2.0:

This boot is perfect for hiking and exploring nature. It can handle any terrain and weather condition thanks to its waterproof and breathable Gore-Tex membrane, durable and grippy rubber sole, and cushioned and supportive footbed. The HAIX Scout 2.0 also features a Sun Reflect system that reduces the heating effect of the sun and a fast lacing system that allows you to adjust the fit easily. With the HAIX Scout 2.0, you can enjoy your outdoor adventures in comfort and style.

This boot is perfect for hiking and exploring nature. It can handle any terrain and weather condition thanks to its waterproof and breathable Gore-Tex membrane, durable and grippy rubber sole, and cushioned and supportive footbed. The HAIX Scout 2.0 also features a Sun Reflect system that reduces the heating effect of the sun and a fast lacing system that allows you to adjust the fit easily. With the HAIX Scout 2.0, you can enjoy your outdoor adventures in comfort and style.HAIX Airpower XR2 Winter:

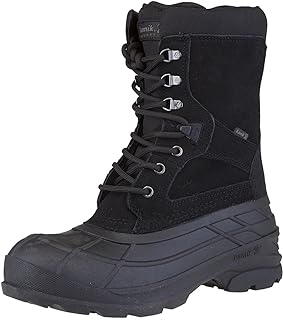

If you work in emergency medical services, the HAIX Airpower XR2 Winter is the ideal boot for you. It provides protection, warmth, and slip resistance in cold and wet conditions, thanks to its waterproof and insulated Gore-Tex membrane, composite toe cap, puncture-resistant midsole, and slip-resistant and shock-absorbing rubber sole. The HAIX Airpower XR2 Winter also features a Climate system that regulates the temperature and moisture inside the boot and a zipper and lacing system that makes it easy to put on and take off. With the HAIX Airpower XR2 Winter, you can perform your duties with confidence and comfort.

If you work in emergency medical services, the HAIX Airpower XR2 Winter is the ideal boot for you. It provides protection, warmth, and slip resistance in cold and wet conditions, thanks to its waterproof and insulated Gore-Tex membrane, composite toe cap, puncture-resistant midsole, and slip-resistant and shock-absorbing rubber sole. The HAIX Airpower XR2 Winter also features a Climate system that regulates the temperature and moisture inside the boot and a zipper and lacing system that makes it easy to put on and take off. With the HAIX Airpower XR2 Winter, you can perform your duties with confidence and comfort.HAIX Black Eagle Tactical 2.0 GTX High:

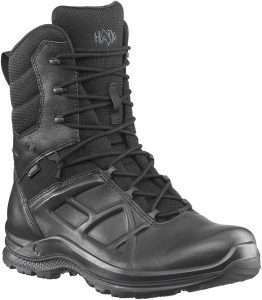

This tactical boot is lightweight, flexible, and durable. It is made of leather and textile, making it waterproof, breathable, and resistant to abrasion. It has a Gore-Tex membrane that keeps your feet dry and comfortable. Also, it has a Sun Reflect system that reduces the heating effect of the sun. The HAIX Black Eagle Tactical 2.0 GTX High also has a rubber sole that provides excellent grip and stability on various surfaces and a cushioned and anatomical footbed that supports your feet and joints. With the HAIX Black Eagle Tactical 2.0 GTX High, you can tackle any challenge with ease and agility.

This tactical boot is lightweight, flexible, and durable. It is made of leather and textile, making it waterproof, breathable, and resistant to abrasion. It has a Gore-Tex membrane that keeps your feet dry and comfortable. Also, it has a Sun Reflect system that reduces the heating effect of the sun. The HAIX Black Eagle Tactical 2.0 GTX High also has a rubber sole that provides excellent grip and stability on various surfaces and a cushioned and anatomical footbed that supports your feet and joints. With the HAIX Black Eagle Tactical 2.0 GTX High, you can tackle any challenge with ease and agility.How to Choose the Right HAIX Boots for You

Consider Your Sector and Purpose:

Consider Your Size and Fit:

Consider Your Style and Preference:

Final Thought

HAIX boots are made by skilled artisans using high-quality materials like leather, rubber, and Gore-Tex. The company caters to various industries, including military, firefighting, law enforcement, forestry, rescue, and outdoor. HAIX boots are rigorously tested and certified for quality and are committed to social responsibility and environmental sustainability. Customers can find HAIX boots by visiting the HAIX website or one of the HAIX dealers or distributors. The company offers a wide range of boots and shoes for different needs and activities. Order your HAIX boots today and experience the difference..

FAQ

Most frequent questions and answers

What are HAIX boots?

HAIX boots are high-quality, durable, and comfortable footwear designed for various sectors and purposes, such as military, firefighting, law enforcement, forestry, rescue, and outdoor activities. They are handmade by skilled craftsmen using the finest materials and the latest technologies.

Where are HAIX boots made?

HAIX boots are manufactured in Germany, Croatia, Romania, and the USA by HAIX employees who follow the principles of social responsibility and environmental sustainability. They undergo rigorous quality control checks and tests to ensure their performance and safety.

How do I choose the right HAIX boots for me?

To select the right HAIX boots for you, consider your sector and purpose, size and fit, and style and preference. You can find more information and guidance on how to choose the right HAIX boots for you on the HAIX website, or you can contact one of the HAIX dealers or distributors who can assist you with your selection and purchase.

What are some of the best models of HAIX boots?

Some of the best models of HAIX boots are:

1. HAIX Scout 2.0: An all-terrain hiking boot that offers waterproof, breathable, and comfortable performance on any trail.

2. HAIX Airpower XR2 Winter: A winterized EMS boot that provides protection, warmth, and slip resistance in cold and wet conditions.

3. HAIX Black Eagle Tactical 2.0 GTX High: A tactical boot that combines lightweight, flexible, and durable design with high-performance features.

How do I take care of my HAIX boots?

To take proper care of your HAIX boots, follow these steps:

– Clean your boots regularly with a damp cloth or a soft brush, and remove any dirt or debris.

– Apply a suitable leather conditioner or wax to your boots, and let them dry naturally.

– Store your boots in a cool and dry place, away from direct sunlight and heat sources.

– Replace your insoles and laces when they are worn out or damaged.

Visit Firesfeet Blog – Your One-Stop Shop for Boot Reviews and Guides!

Here, we empower firefighters with the right boots for their needs. Our collection includes a variety of styles and sizes, guaranteeing the perfect fit for anyone. We take pride in our product quality, ensuring that our boots stand the test of time. With Firesfeet, you can confidently shop for wildland firefighting boots. Visit us today and discover why we are the most trusted source for firefighters looking to take on any challenge wearing firefighting footwear!

Keep yourself safe out there!

#WildlandFirefighters #SafetyFirst #Firesfeet#